What issues should be considered in the preparation of precision mechanical shaft parts processing technology? This is a problem encountered in the machining of shaft parts. It should be considered clearly before the start of processing. Only by making full preparation in advance can make the shaft parts be correctly CNC machined, so as to avoid errors in processing and improve the efficiency.

Process analysis of CNC machining for part drawings, the specific contents are as follows:

(1) Whether the dimension marking method in the part drawing is suitable for the characteristics of CNC machining;

(2) Whether the geometric elements constituting the outline in the part drawing are sufficient;

(3) Whether the reliability of the positioning reference is good;

(4) Whether the machining accuracy and dimensional tolerance required by the parts can be guaranteed.

For parts blanks, processability analysis is also carried out, specifically:

(1) Analyze the adaptability of the blank in terms of installation and positioning, as well as the size and uniformity of the margin;

(5) Whether the machining allowance of the blank is sufficient, and whether the allowance is stable during mass production.

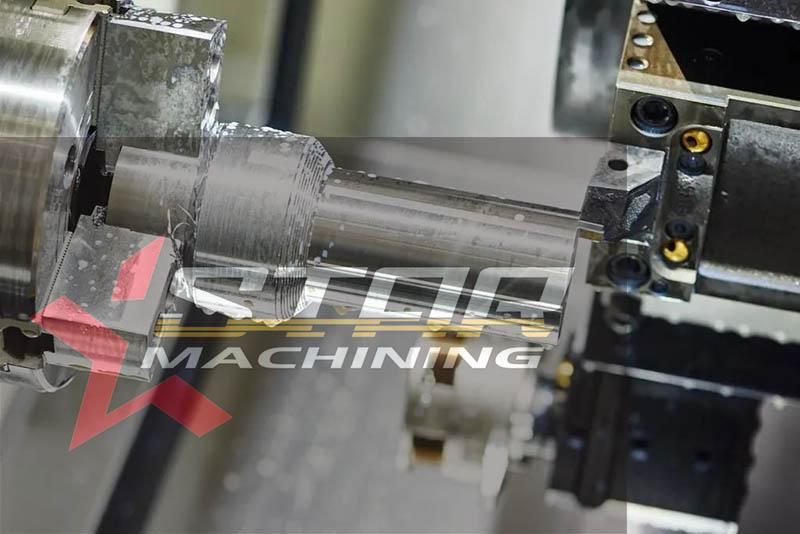

1. Selection of machine tools

Different parts should be processed on different CNC machine tools, so the CNC machine tool should be selected according to the design requirements of the parts.

2. Selection of tool setting point and tool changing point

When CNC programming, the workpiece is regarded as stationary, while the tool is in motion. Usually the tool setting point is called the program origin. The selection points are: easy alignment, convenient programming, small tool setting error, convenient and reliable inspection during processing, and the tool setting point should coincide with the tool position point during tool setting.

3. Selection of cnc machining method and determination of cnc machining plan

The selection principle of the machining method is to ensure the processing accuracy and surface roughness requirements of the processed surface, but in actual selection, it should be considered in combination with the shape, size and heat treatment requirements of the parts.

When the machining plan is determined, the processing method required to meet these requirements should be preliminary determined according to the accuracy and roughness requirements of the main surface.

4. Selection of machining allowance

Machining allowance: The amount generally refers to the difference between the physical size of the blank and the size of the part.

There are two principles for the selection of machining allowance, one is the principle of minimum machining allowance, and the other is that there should be sufficient machining allowance, especially for the last process.

5. Determination of cutting amount

Cutting parameters include depth of cut, spindle speed, and feed. The cutting depth is determined according to the rigidity of the machine tool, fixture, tool and workpiece, the spindle speed is determined according to the allowable cutting speed, and the feed rate is determined according to the machining accuracy and surface roughness requirements of the part and the material properties of the workpiece.

Dongguan Star Machining Company limited mainly provides high-precision casting molds and precision parts for automobile, rail transit, intelligent equipment and other industries. After years of development, we have accumulated rich experience in R & D design and precision parts manufacturing, and have an experienced team, complete production equipment and testing equipment.Welcome to visit and send inquiries!

Post time: Jun-19-2023