What we do

Star Machining Technology is a professional mold manufacturer, specializing in large and complex molding, we provide one-stop mould solution, which include mould component mechanical design, mold design, mold fabrication, plastic or casting component manufacturing and secondary processing services.

At Star Machining Technology, we have the deep experience of designing and specifying the construction of aluminum die casting molds and injection molds. We begin mold making early on by working with you to determine the manufacture-ability of a design. We’ll also help establish performance criteria for the finished part. This upfront involvement in the die casting mold design and analysis process helps to ensure product quality. We can generate detailed tooling designs, part prints and specifications from your prototype, or your 2D or 3D CAD files. Our master mold makers give you the best of both worlds: leading edge process and equipment in the hands of skilled and experienced craftsmen. Our exacting mold design and precision construction abilities translate into a manufacturing system that produces component parts of outstanding quality. When you commission Star Machining Technology to build your molds, you are assured of parts with consistent performance and maximum return on your tooling investment.

We also understand that highly featured, tight-toleranced parts, with aggressive lead times, require top quality tooling—from the first production run through the life of your product. Whether we’re building a mold for a one-off prototype or a multi-cavity, full frame production mold, exceptional tooling is at the heart of Star Machining Technology’s die casting molding and injection molding operation.

Our Engineering Capabilities Include:

Part Design: We develop products that maximize cost-effective tooling

Flow Analysis: We perform plastic melt flow analysis with Moldex3D

Mold Design: All designs are created using Creo Parametric

Research & Standards: We maintain a library of individual customer standards

Progress Reporting: Charts and regular progress updates made available

Electronic Data Transfer: FTP and email attachments available

Maintain and update CAD

Types of Molds We are Offering

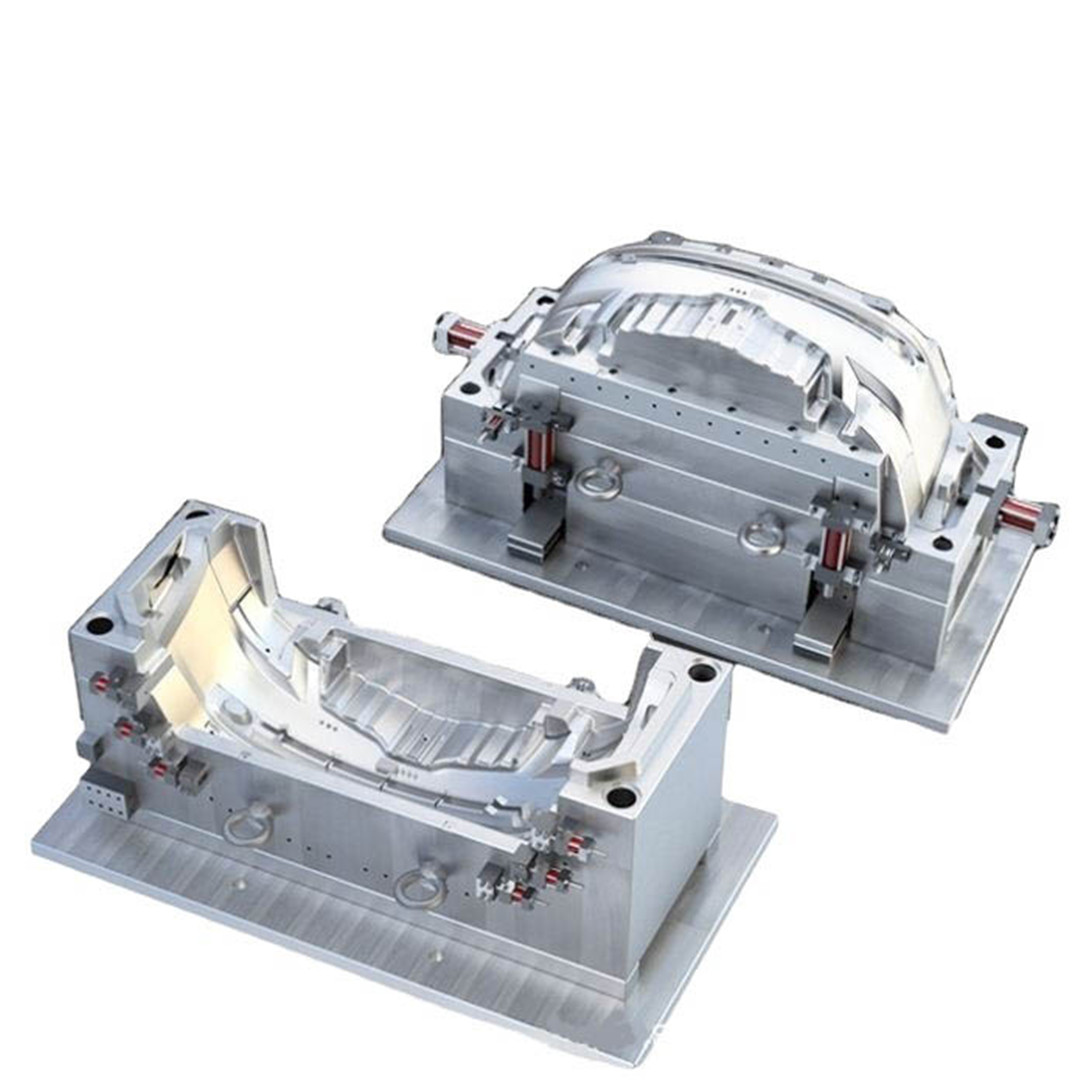

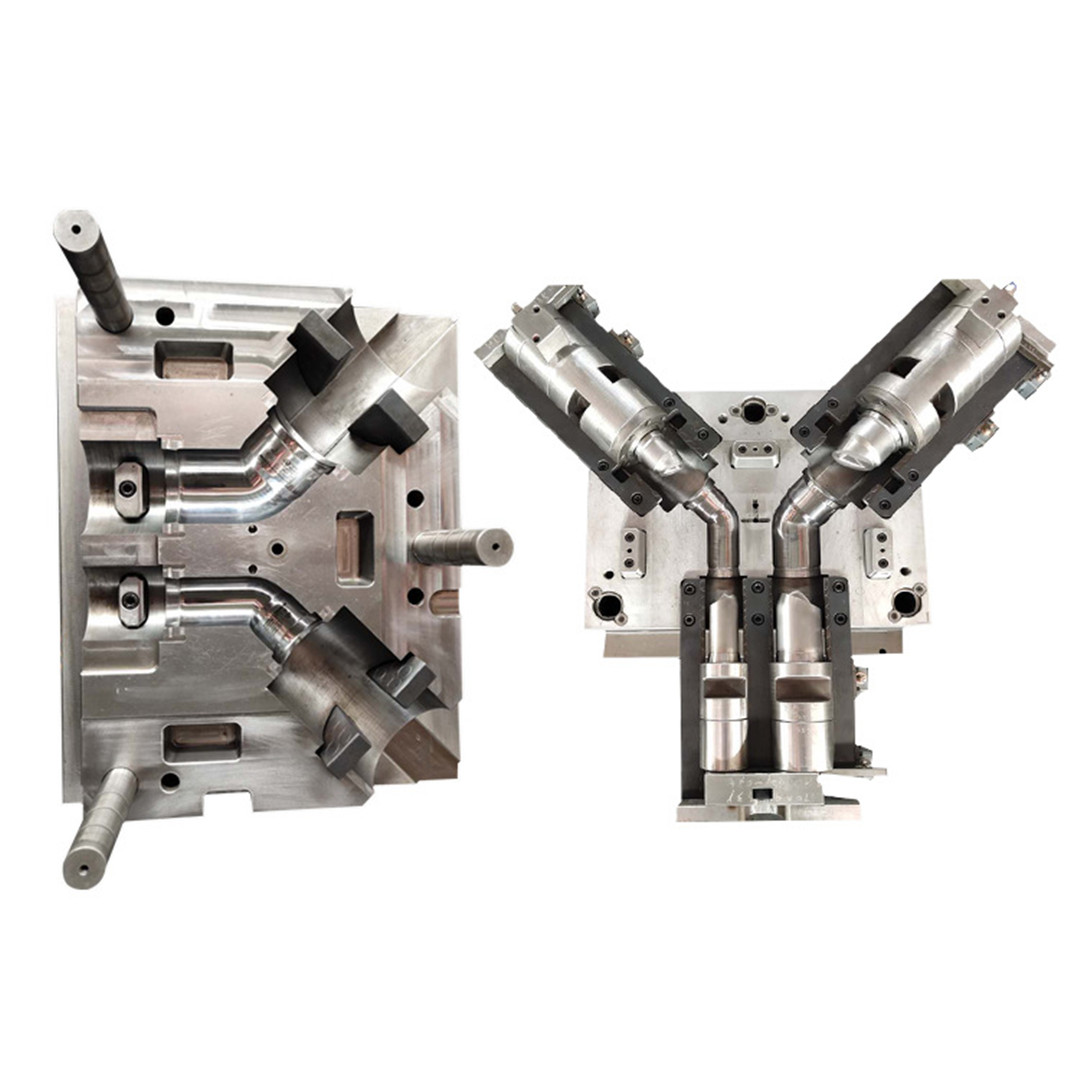

Die Casting Mold

Unlike many prototyping specialists, we can provide metal casting molds (and a low-volume casting service through our partners). These molds — typically made from hardened steel — can be used to make parts from aluminum, zinc, magnesium and other non-ferrous metals.

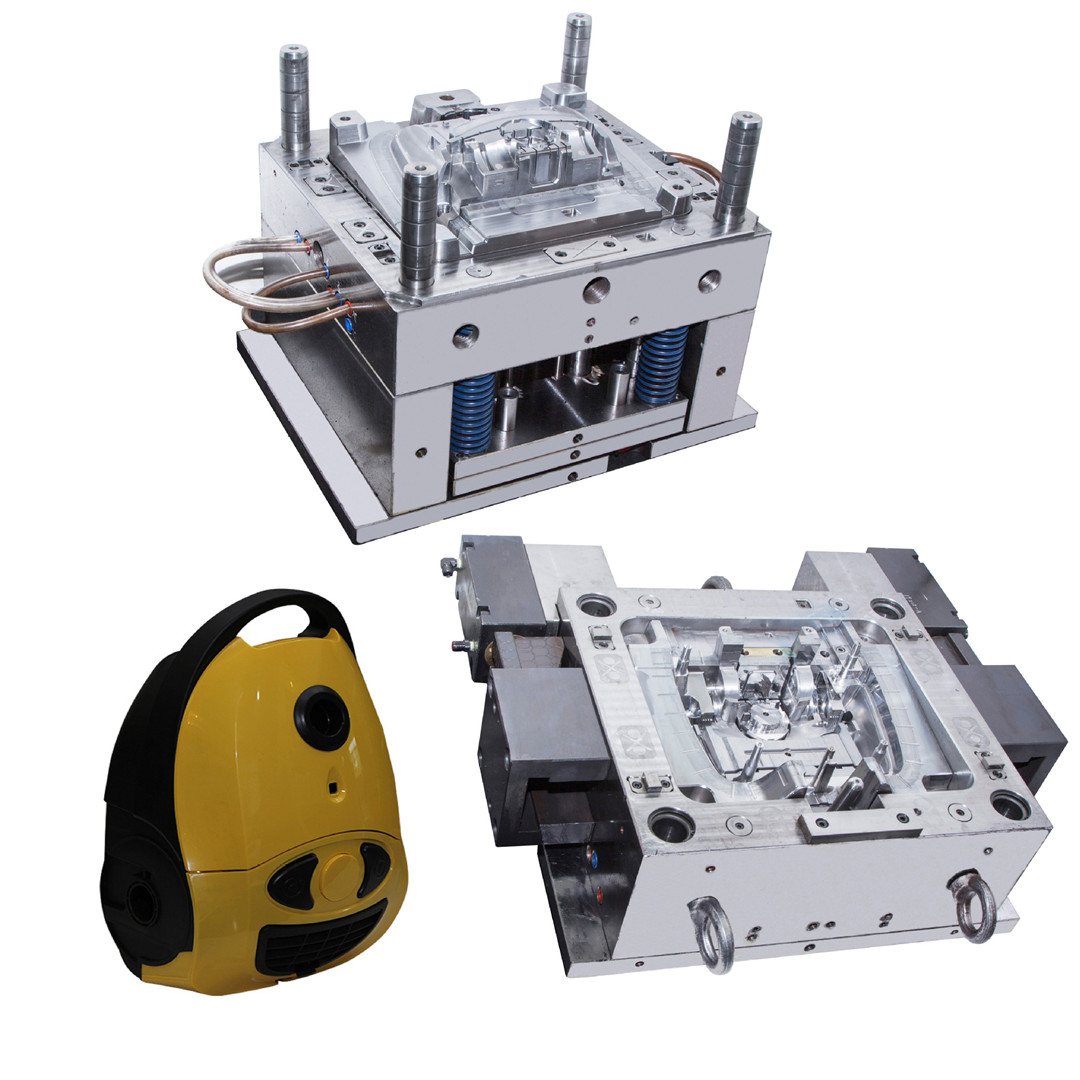

Plastic Injection Mold

Plastic injection molds are aluminum or steel molds used to make parts from a wide range of plastics, including nylons, acrylics, elastomers and reinforced materials like glass-filled polyamide. Custom plastic molds can last between 10,000 and 1,000,000 shots.

Mold Making Processes

Mold making is a complex process that requires a high level of skill and experience. Although each case is different, a typical order for a set of molds may go something like this:

1. DFM

As soon as the customer confirms the order of molds, we will start to do an initial analysis of the parts to get an idea of the part line, gate positions, etc.

2. Mold design and mold flow analysis

The second step involves the use of predictive modeling software which allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design.

3. CNC machining and EDM

We make the first molds using high-quality machining equipment, with the plastic, steel, aluminum, etc. chosen by the customer.

4. T1 sample

With the newly made molds, we make a T1 sample to have a clear vision of how the customer’s final molded parts will turn out.

5. Improvement if necessary

Based on our analysis of the T1 sample, we review the mold design and make any adjustments needed.

6. Commence production and shipping

We manufacture the molds in accordance with the final specifications before shipping them to the customer.