What is Precision casting

Precision casting is a casting method relative to the traditional casting process. It can obtain relatively accurate shape and high casting precision. The more common practice is: first design and manufacture a mold according to the product requirements (with very little or no margin), cast wax by casting, and obtain the original wax mold; repeat the coating and sanding on the wax mold Process, hardening the shell and drying; then melt the internal wax mold to dewax and obtain the cavity; roast the shell to obtain sufficient strength; pour the required metal materials; High-precision finished product. According to product needs or heat treatment and cold working.

Like general casting process design, the tasks of investment casting process design are:

(1) Analyze the manufacturability of the casting structure;

(2) Select a reasonable process plan, determine the relevant casting process parameters, and draw the casting diagram on the basis of the above;

(3) Design the pouring system and determine the module structure.

Investment casting process flow

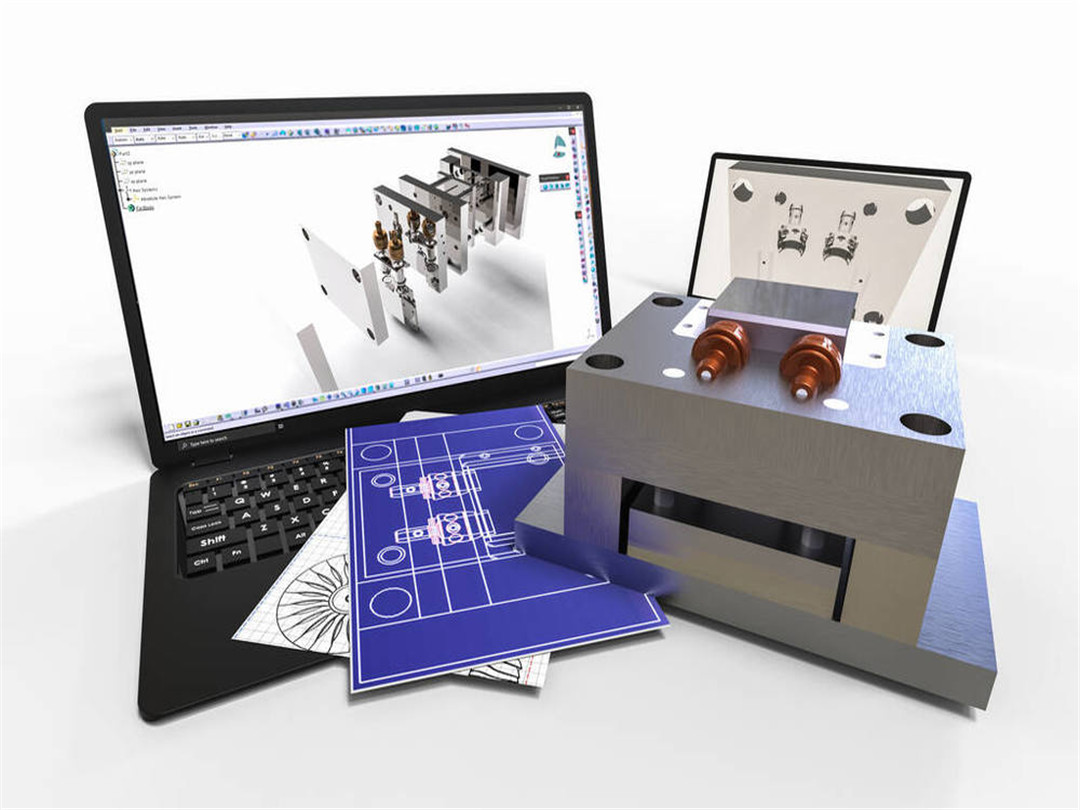

Mold design - mold manufacturing

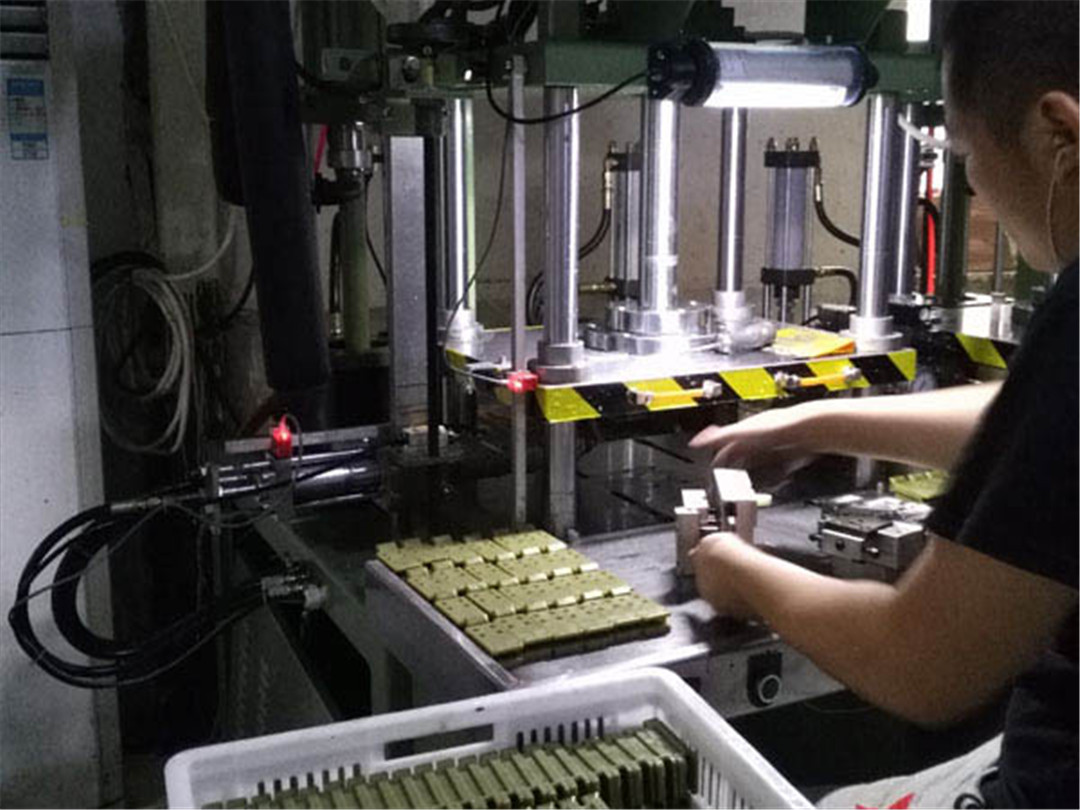

wax injection - wax repair - wax inspection

The process begins with production of a heat disposable pattern. This pattern is usually made by injecting wax into a metal die or mold. Pattern is injected in Horizontal Automatic Injection Machine.

Pattern assembling

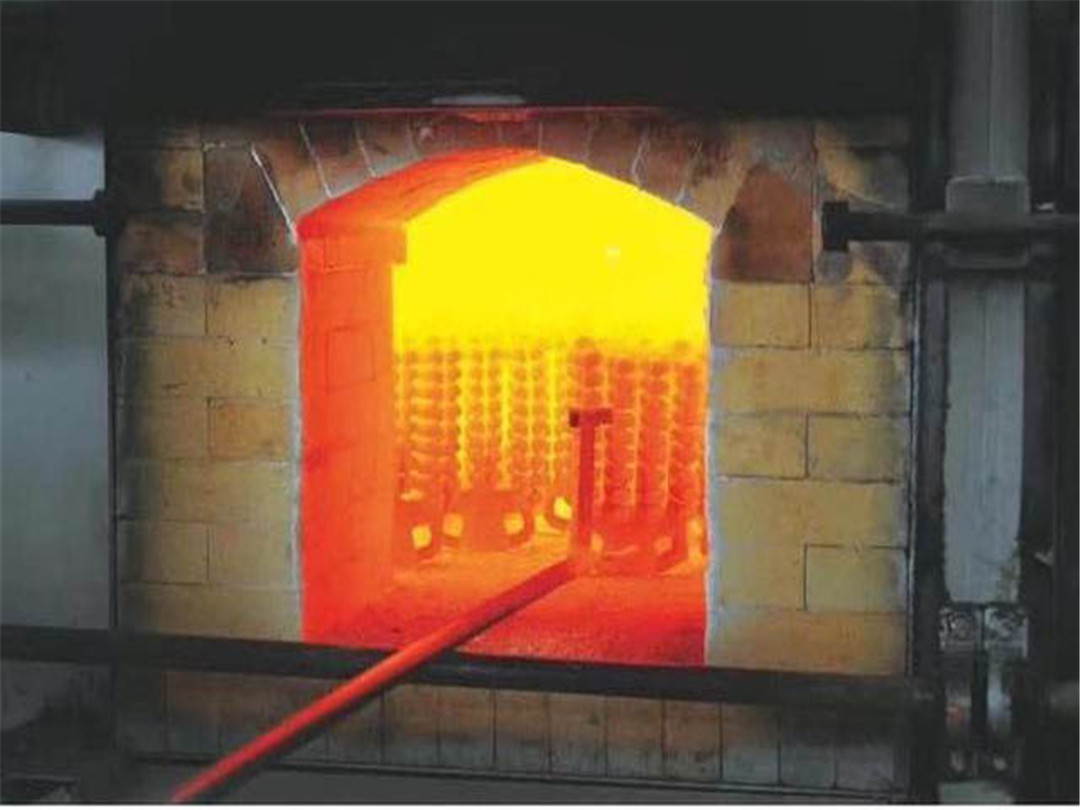

Dewaxing (steam dewaxing)

mold shell roasting

Pouring (pouring molten steel in the mold shell)

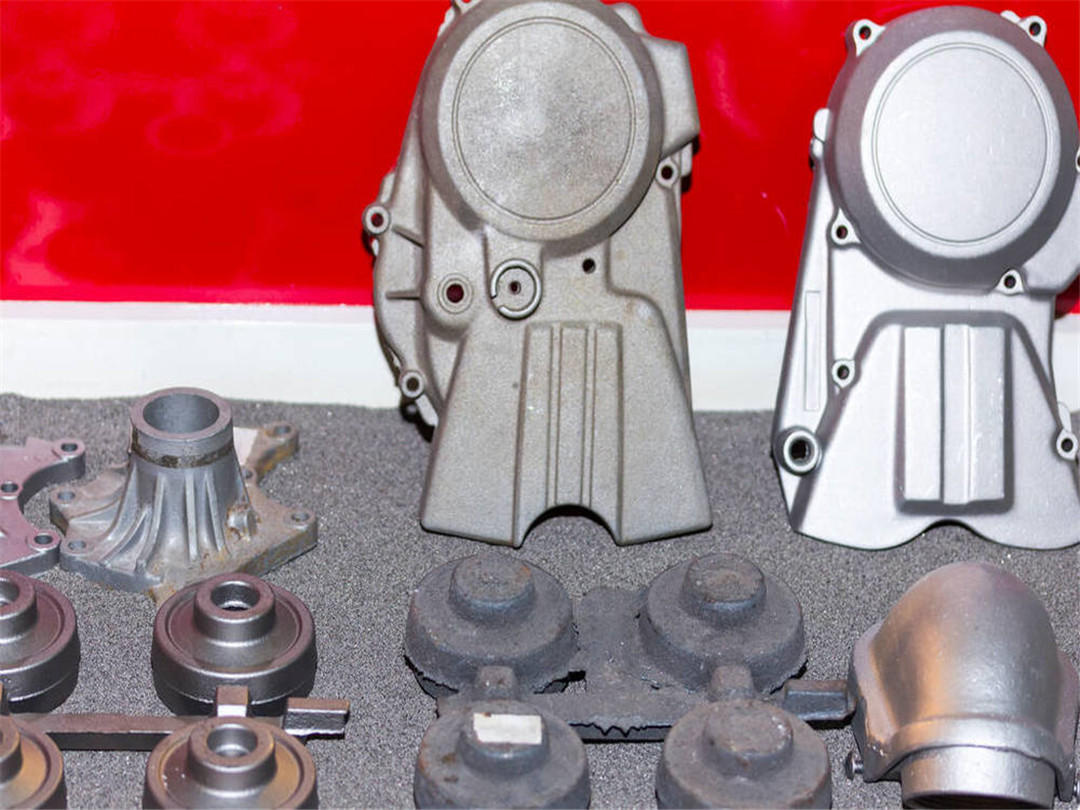

Casting gate cutting and grinding

Shot blasting

Measurement control

Final inspection and packing

Why choose us for your precision casting manufacurer

● Production capacity: we have 1,000 tons annually production capacity

● Strong Engineering team support: can make your part better dimensional accuracy and surface finish.

● Quike Reply: we provide you a whole solutions within 24 hours.

● Wide size and low thinkess allowed: 0.25 inches to 6 inches available, wall thikness as low as 0.020 inches

● Less time: Prototypes to production runs in as little as 4~6 weeks

● Large Production: Prototype quantites to large production runs

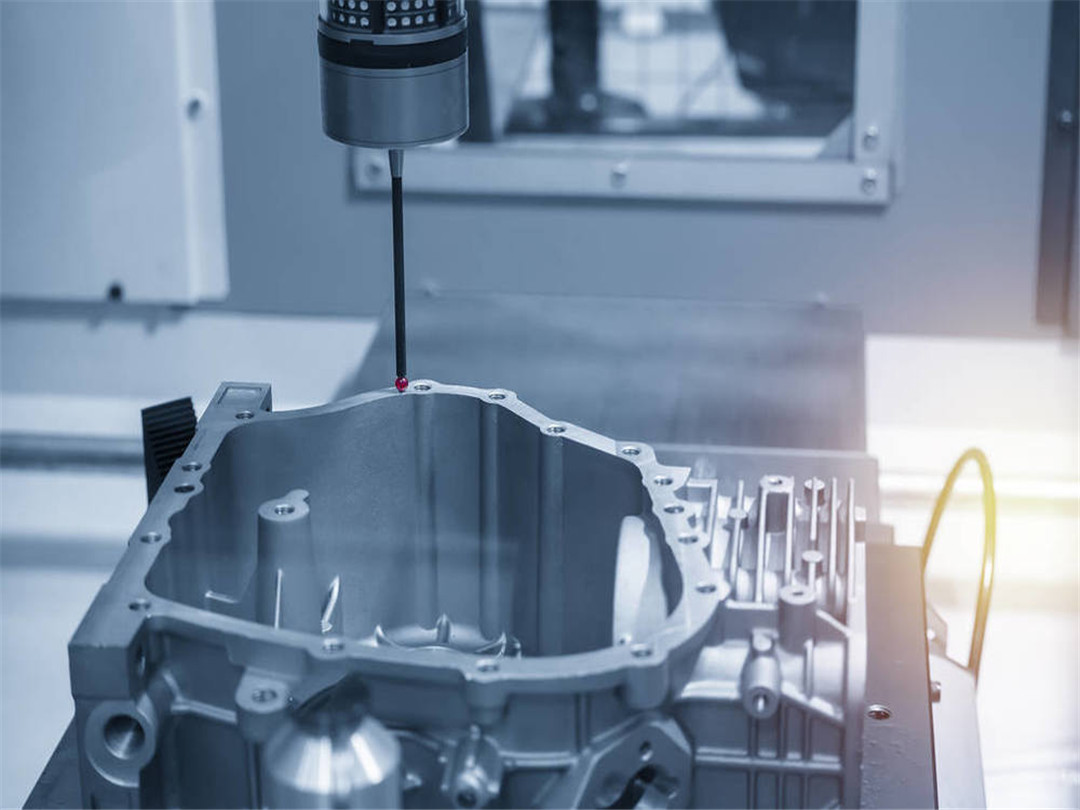

● Inspection: 100% strict inspection before shipment

● We have a huge amount of precision CNC machines for post-machining

We are your good development partner, willing to share our thoughts and ideas about product design, material choice, measurements or machining

Casting Materials & Finishes

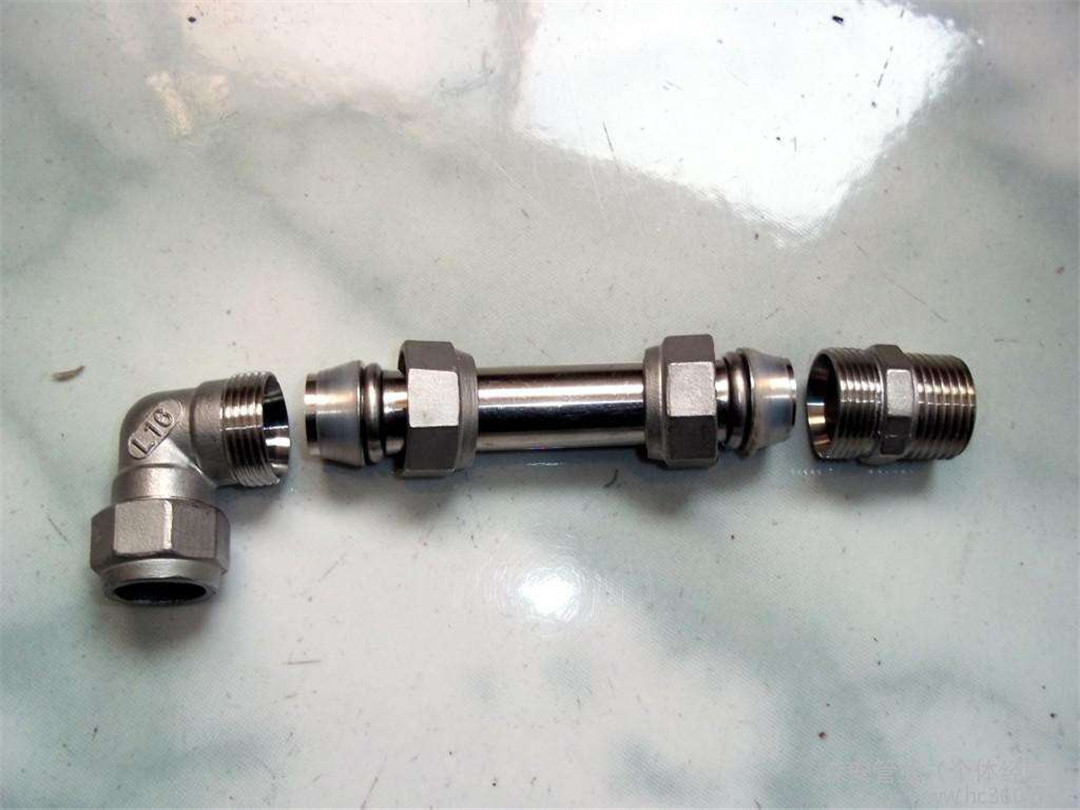

Materials: 300 and 400 series stainless steels, copper or brass, Nickel, tool steels, carbon steels, low alloy steels…

Finishes: Sandblasting, polishing, powerder coating, painting, plating