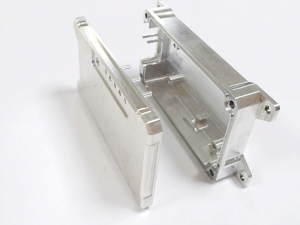

Plastic injection molding part Remote control housing

Product Specification

| Product Name | Remote control housing |

| Material | ABS plastic |

| Manufacturing process | Molding injection |

| Surface Treatment | Burrs removing |

| Mold Cavity | Single or multiple |

| Tolerance | +/-0.02mm |

| Mold life | 300,000~1000,000 shots |

| Surface Roughness | Min Ra0.1~3.2 |

| Drawing Accepted | STP, STEP, LGS, XT, AutoCAD(DXF,DWG), PDF, or Samples |

| Usage | Electronics |

| Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

| Quality Assurance | ISO9001:2015, SGS, RoHs |

| Payment Terms | Trade Assurance, TT/PayPal/West Union |

Star Machining Technology has served in consumer electronics industry for many years. We offer innovative prototyping and reverse engineering services, and we produce precision parts and complex assemblies for consumer electronics components such as projector housing, plastic shell, and other precison plastic parts.

Packaging & Delivery

Packaging: One piece in a PE bag or with tissue paper, customized blistered packaging or corrugated clapboard packaging. Less than 22 KGS in a carton.

Delivery: The samples delivery is about 7~15 days and the lead time for mass production is about 25-40 days.

FAQ

● Does your company have any sort of quality certification?

Yes, we are ISO9001:2015 quality certified.

How long is the lead time for the mold?

It depends on the mold`s size and complexity. Normally the lead time is 25~35 working days. If the molds are very simple and not in big size we can work out within 15 working days.

● I have no 3D drawing, how should I star the new project?

You can provide us a sample we will help finish the 3D drawing design information

● Can I get a sample for check?

Sure, before mass production we will charge you some sample fee, when you confirm the order or tooling fee we can send you a sample for free.

● Do you design the products?

Product designs and drawings are provided by the customer.

● How can I be confident in your quality?

We have an established quality system and are committed to customer satisfaction and continual improvement. All our products are subjected to in-process inspections at various stages of production by well-trained and qualified operators.

related products

-

Tel

-

E-mail

-

Whatsapp

-

WeChat

WeChat

-

Top