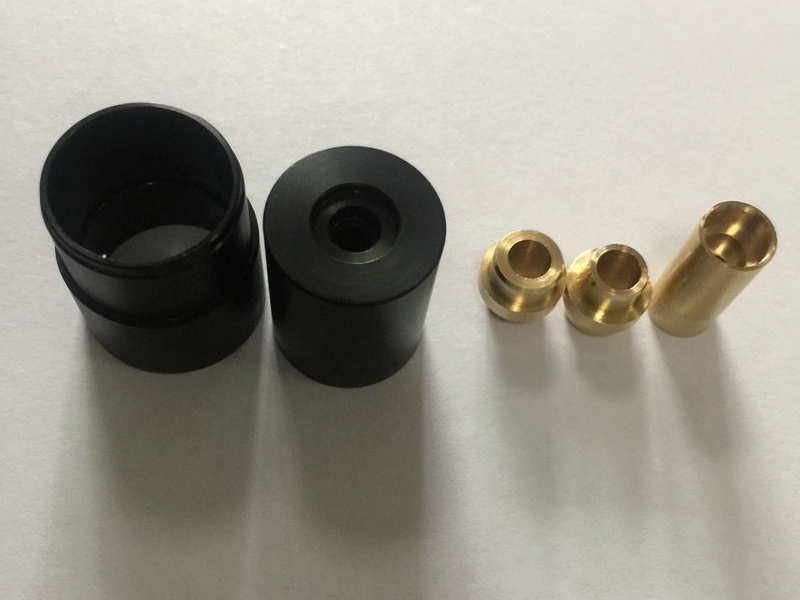

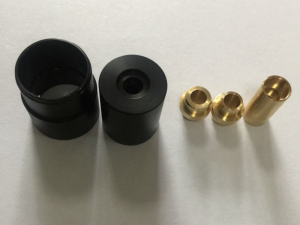

CNC turning medical components Forehead therometer parts

Product Specification

| Product Name | CNC turning medical components Forehead therometer parts |

| Material | Brass, peek |

| Manufacturing process | CNC machining (CNC turning, cnc milling) |

| Surface Treatment | Burrs removing |

| Tolerance | +/-0.002~+/-0.005mm |

| Surface Roughness | Min Ra0.1~3.2 |

| Drawing Accepted | STP, STEP, LGS, XT, AutoCAD(DXF,DWG), PDF, or Samples |

| Usage | Medical equipment |

| Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

| Quality Assurance | ISO9001:2015, SGS, RoHs |

| Payment Terms | Trade Assurance, TT/PayPal/West Union |

Star Machining Technology has served medical instrument suppliers for many years. We offer innovative prototyping and reverse engineering services, and we produce precision parts and complex assemblies for medical components such as precision pins, fittings, stainless connectors, shafts, plastic shell, housing…and so on.

Packaging

200pcs in a PE bag and then put them in each layer of clapboard, and in a carton which is no more than 22kgs.

FAQ

● Are you ISO cerified?

Yes, we are ISO 9001: 2015 certified.

● What information do you need for a quotation?

To make a good quotation, we will need the following things:

1.Product drawings or 3D model data files.

2. The quantity of products you are going to make.

● What design files can you accept from our company?

Most CAD based programs, e.g. DWG, DXF, IGES and most commonly used formats.

● What types of material can be machined for medical components in your company?

Normall aluminum, stainless steel, brass, titanium, Nickel Alloys and all kind of Plastic material can be machined. We will discuss according to your detailed requirement.

● Are your measuring equipments calibrated and up to date?

Yes, they are.

● What are your normal lead times?

Depending on the part complexity and capacity of our company typical lead times range from 4-8 weeks after receipt of order.

● Why should we buy our components from you?

We have an proven track record of supplying quality parts on-time and at very competitive prices. We fully understand the price pressure put on all of us. We work diligently toward trimming costs everywhere possible on a daily basis. We also understand that our customers need 100% reliable performance from their suppliers. All things considered, we think you will find that Star Machining offers some of the best value and dependability in the business.

Company overview/Profile

Founded in 2002, located in Dongguan city, Guangdong province of China, Dongguan Star Machining Technology Co., Limited specializes in precision-machined components and molds developing & manufacturing from the aerospace industry to custom projects. We continue to focus on quality and customer service as we upgrade our capabilities and extend our capacities by acquiring more capable and efficient machinery and equipment.

Star Machining works with a large variety of materials including steel, stainless, aluminum, brass, delrin, lexan and others. Our reputation is built on over 15 years of continuous excellent service, providing top quality CNC milling, CNC turning, precision casting, injection molding and precision engineering to a diverse range of clients.

We love our clients and they love working with Star Machining Technology Company. The companies below have co-operations with in Star Machining as a valued, trusted, strategic PR company. They enjoy increased visibility, credibility and profits as a result of our public relations campaigns.

related products

-

Tel

-

E-mail

-

Whatsapp

-

WeChat

WeChat

-

Top