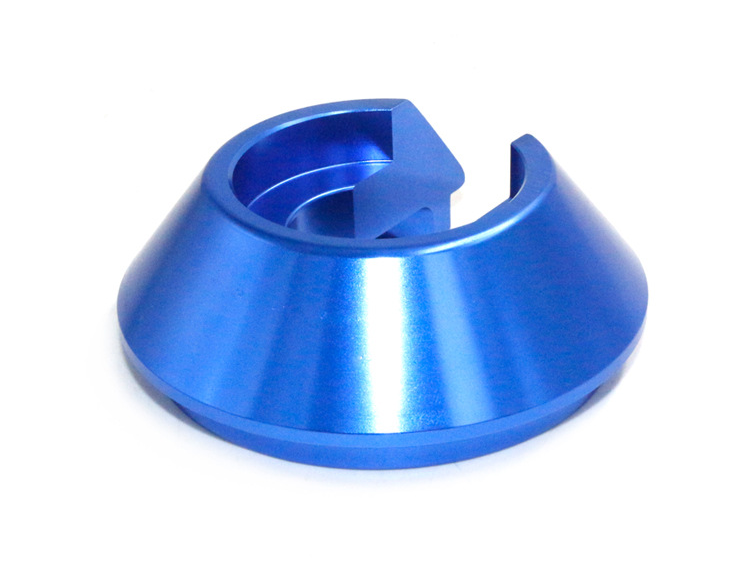

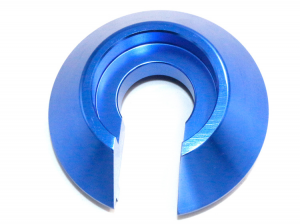

CNC machining shock absorber part spring plate

Product Specification

| Product Name | Blue anodized cnc machining spring plate |

| Material | Aluminum 6061-T6 |

| Manufacturing process | CNC turning, CNC milling |

| Surface Treatment | Blue anodizing |

| Tolerance | +/-0.002~+/-0.005mm |

| Surface Roughness | Min Ra0.1~3.2 |

| Drawing Accepted | STP, STEP, LGS, XT, AutoCAD(DXF,DWG), PDF, or Samples |

| Usage | Shock absorber |

| Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

| Quality Assurance | ISO9001:2015, SGS, RoHs |

| Payment Terms | Trade Assurance, TT/PayPal/West Union |

The shock absorber is used in automobile, motorcycle and race car suspension systems. It is a key suspension system component to ensure a stable vehicle operation, as it ensures an excellent wheel grip and efficient steering and braking performances in order to improve vehicle safety levels. Star Machining offers a variety of shock absorber parts, including cylinder heads, high speed adjusters, bracket reservoirs, guide rings, spring platforms, gas piston set tools, and valve double bleed.

Packaging & Delivery

Packaging: one piece with tissue paper and then in a plastic tray, 4 or 5 layers in a carton which is no more than 22kgs.binding cartons with belts if by air, palletlizing cartons if by ocean.

Delivery: The samples delivery is about 7~15 days and the lead time for mass production is about 25-40 days.

FAQ

Are you ISO cerified?

Yes, we are ISO 9001: 2015 certified.

Can I require a breakdown including the material cost and expected machined time of the parts?

We don’t generally provide the breakdown list like this. But we can provide it to you after discussion if really necessary.

What are your core competencies?

We offer high speed precision turning, milling, and assembly of component parts.

What design files can you accept from our company?

Most CAD based programs, e.g. DWG, DXF, IGES and most commonly used formats.

What are your normal lead times?

Depending on the part complexity and capacity of our company typical lead times range from 4-8 weeks after receipt of order.

related products

-

Tel

-

E-mail

-

Whatsapp

-

WeChat

WeChat

-

Top