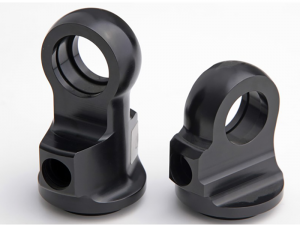

CNC machining Aluminum piston for shock absorber

Product Specification

| Product Name | CNC machining aluminum Floating piston |

| Material | Aluminum 6061-T6 |

| Manufacturing process | CNC turning |

| Surface Treatment | Burrs removing |

| Tolerance | +/-0.002~+/-0.005mm |

| Surface Roughness | Min Ra0.1~3.2 |

| Drawing Accepted | STP, STEP, LGS, XT, AutoCAD(DXF,DWG), PDF, or Samples |

| Usage | Shock absorber |

| Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

| Quality Assurance | ISO9001:2015, SGS, RoHs |

| Payment Terms | Trade Assurance, TT/PayPal/West Union |

Star Machining produces and supplies shock absorber components of any complexity, which are used in trucks, cars, motorcycles and quadbikes. Over the years we have proven ourselves as a reliable supplier operating on markets of Europe, Canada, US. The technical capabilities of our company allow us to produce shock absorber parts in exact accordance with client’s requirements.

Packaging & Delivery

Packaging: with or not with tissue paper and then in a plastic tray, 4 or 5 layers in a carton which is no more than 22kgs. If customer need we do palletizing in house per request.

Delivery: The samples delivery is about 7~15 days and the lead time for mass production is about 25-40 days.

FAQ

● Are you ISO cerified?

Yes, we are ISO 9001: 2015 certified.

● How long can I expect to receive a quote?

We can generally quote you back within 24 hours in most cases. Depending on the complexity of the project, we ensure to send you a competitive quote no exceed 48 hours.

● How can I get some samples?

For some parts we can provide you samples for free, for some parts we would charge some labor cost, we look forward to having long-term cooperation with our customers.

● What Parts Make Up the Suspension System?

Tires ,Coil springs, Shock absorbers, Rods/linkages and Joints/bearings/bushings make up the suspension system. We make all kinds of shock absorber parts which need high precision and high quality in this system.

● Can you supply completed parts?

Yes, when extra details such as plating, anodizing, powder coating, etc are required we co-ordinate with our existing subcontractors who specialize in their given field. We can therefore serve as a one-stop-shop with only one account.

● What are your core competencies?

We offer high speed precision CNC turning, CNC milling, and assembly of component parts.

related products

-

Tel

-

E-mail

-

Whatsapp

-

WeChat

WeChat

-

Top